Solution

Medical Innovation and Compliance

Moreover, CNC machining's rapid prototyping capabilities empower medical device designers to swiftly iterate through designs, leading to faster innovation and reduced time-to-market.

The technology's repeatability and consistency in producing high-quality parts contribute to meeting stringent regulatory standards, enhancing patient safety, and instilling confidence in medical professionals

Precision Redefined

In the realm of surgical instruments, CNC machining ensures the precise fabrication of tools that surgeons rely upon for delicate procedures. The technology's ability to work with a diverse range of materials, including biocompatible ones, allows for the creation of tools that are not only reliable but also compatible with the human body.

High Precision

We offer unmatched precision, ensuring that satellite components are manufactured to exact specifications. This precision is critical for components like antennas, receivers, transmitters, and other devices to operate optimally.

Faster Cycle Times

By automating processes and our cutting edge technology, we quotes in minutes and parts in days, Communications engineers can reduce cycle times by as much as 60% with Kintec.

Leading Quality

Quality services include MTRs, FAI reports, Dimensional Inspection Reports, certificates of conformity, advanced inspection reports and more.

High-volume Production

High-volume production refers to a manufacturing process that is optimized for producing a large quantity of products or components within a relatively short period of time. This approach is typically used when there is strong demand for a particular product, and economies of scale can be achieved by producing a high volume.

High volume manufacturing is often used for products that have high demand, such as electronics or car parts. High-volume production may not be suitable for all types of products. Some products, especially those with niche markets or high customization requirements, may benefit from low-volume or custom production methods.

Kintec's High-volume Production Sevice

1. Quick turnaround time

2. Cost-effective for large orders

3. Quality Assurance

4. Enhance Your Market Competitiveness

5. Scalability Tailored to Your Production Needs

Advantages of High-volume Production

It’s important to note that while high-volume manufacturing offers many advantages, it may not be suitable for all products or industries. Some products, such as custom or niche items, may benefit more from low-volume or specialized production methods.

Quick Market Response

Quick Market Response

With the ability to produce large quantities rapidly, high-volume manufacturing can respond quickly to shifts in market demand, ensuring that products are readily available to customers.

Competitive Pricing

Competitive Pricing

Lower production costs enable businesses to offer competitive prices to customers, potentially gaining a competitive advantage in the market.

Efficiency

Streamlined and optimized processes in high-volume manufacturing increase production efficiency. This results in faster production cycles and shorter lead times.

Product Standardization

Product Standardization

High-volume production often relies on standardized components and processes, simplifying quality control and reducing the likelihood of defects.

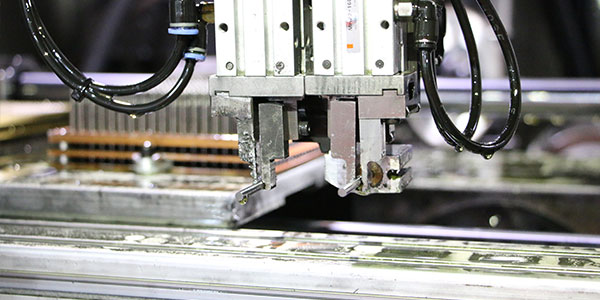

Kintec’s CNC Machining Projects

Trusted by Industry Leaders